VACUUM VALVES

Alluminium – Magnesium

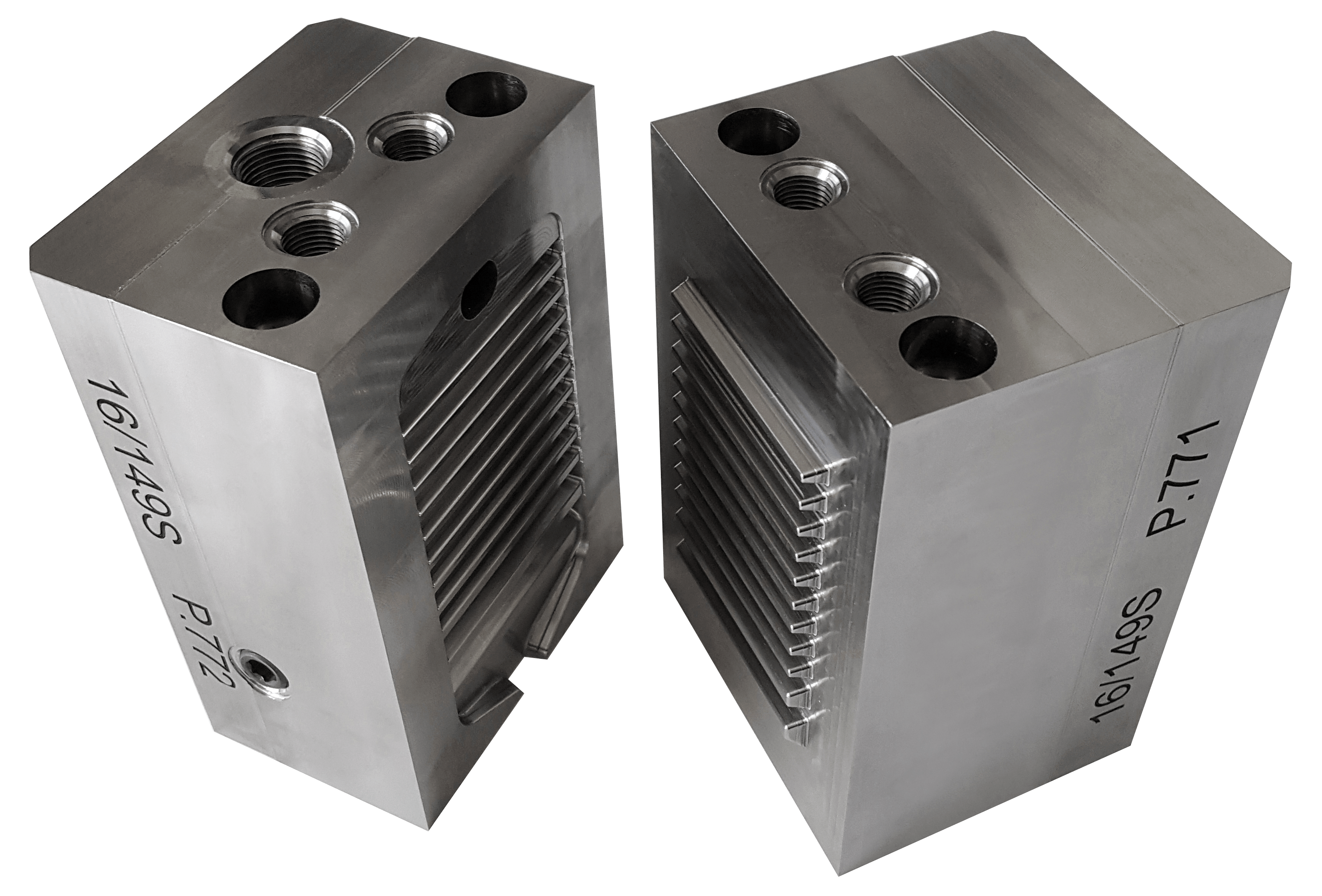

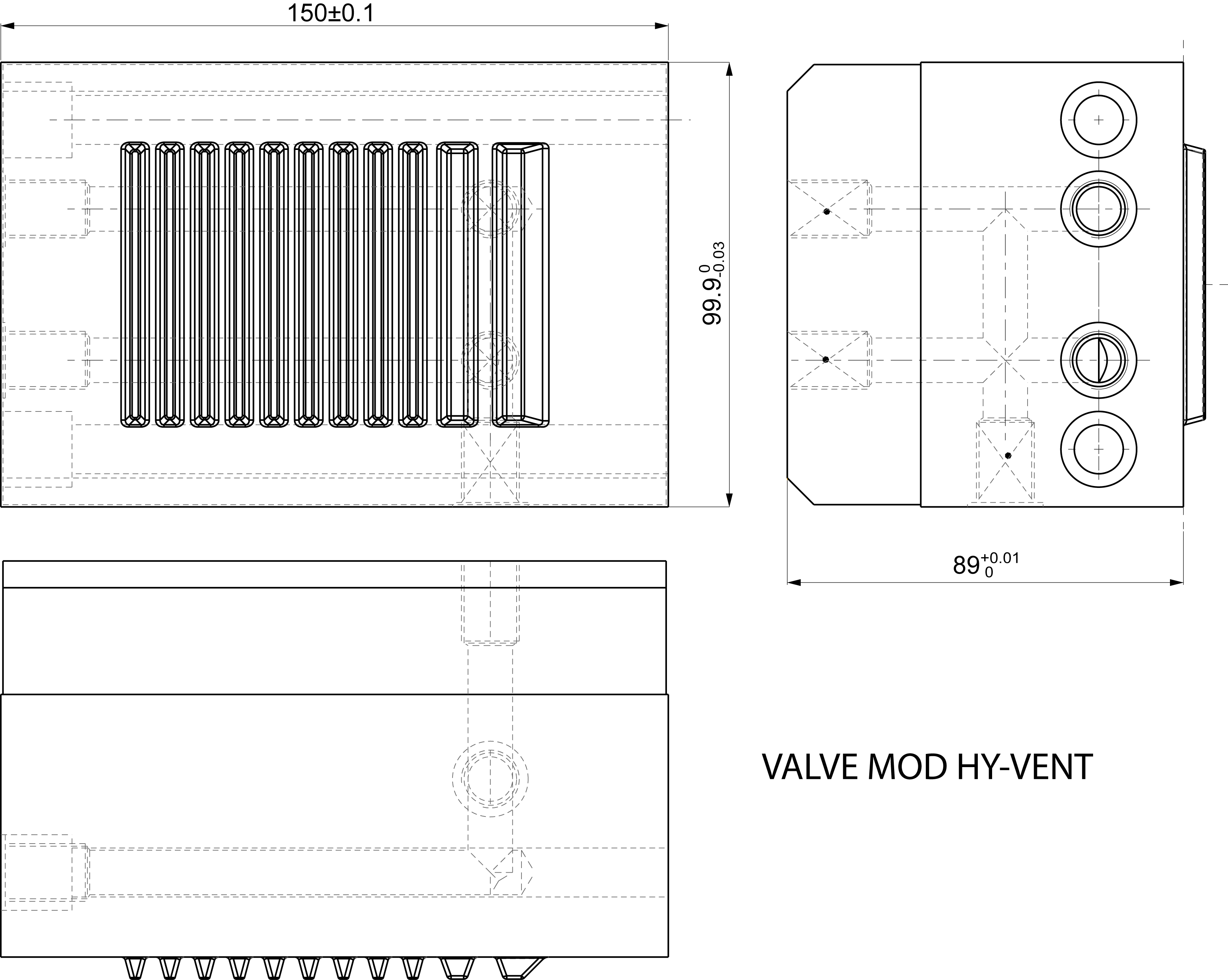

HY-Vent

The Fondvacuum® valves guarantee maximum air suction and duration, with reduced need of maintenance. with proper usage, they can be used for approximately 20,000 cycles without maintenance.

Modern diecasting faces critical procedural issues – such as the reduction of the refuse caused by porosity. Porosity can have different root causes, such as air incorporated during the injection process.

Internal porosity can have dimensions ranging from a few microns to a few millimeters, causing subsequent poor surface quality that can be seen during the extraction and even after thermal surface treatments.

The presence of air also creates a counter-pressure generated in the filling phase, which can cause cold joints or incomplete fillings.

A solution to these problems is given by our Fondvacuum®️ HY-VENT (Hybrid venting).

The Fondvacuum®️ HY-VENT (Hybrid venting) valve combines the capability of air evacuation systems of normal valves with the efficiency of the active vacuum obtained from the Fondvacuum®️ suctioning units.

Thanks to their innovative design, Fondvacuum®️ HY-VENT valves are able to guarantee a high performance in air evacuation from molds and a fast aluminum solidification. Furthermore, Fondvacuum® HY-VENT valves are able to endure intensive usage at high temperatures thus, allowing for long periods of time without maintenance.