VACUUM UNIT FOR DIE CASTING

Aluminum – Magnesium – Copper Alloys

Serie D2 – Next P50/P75

Performances vacuum system for diecasting of non-ferrous metals (aluminum, magnesium, copper alloys)

D2 NEXT vacuum control unit operating features:

- Wide range of applicability in die casting processes (presses from 150 to 3000 tons and above*)

- Industrial PC

- Monitor touch screen 10″

- User-definable tank vacuum level

- Download/upload data on USB media

- Remote network accessibility

*Possibility of upgrade (tank and pump)

Structural characteristics:

- Frame made entirely in stainless steel AISI 304

- Tank in stainless steel AISI 304

- Tank volume approximately 660 L

- Vacuum pump of 50 m3 up to 70 m3

- Double stainless steel grid filter to ensure a better filtration from metal particles and polluting gas (i.e. oil mist)

- Wide lid to inspect vacuum chamber

- Possibility to expand vacuum tank

Controls and measurements:

- Vacuum measurement and control by channel

- Measurement and control of suction capacity per channel

- Pollution control by channel

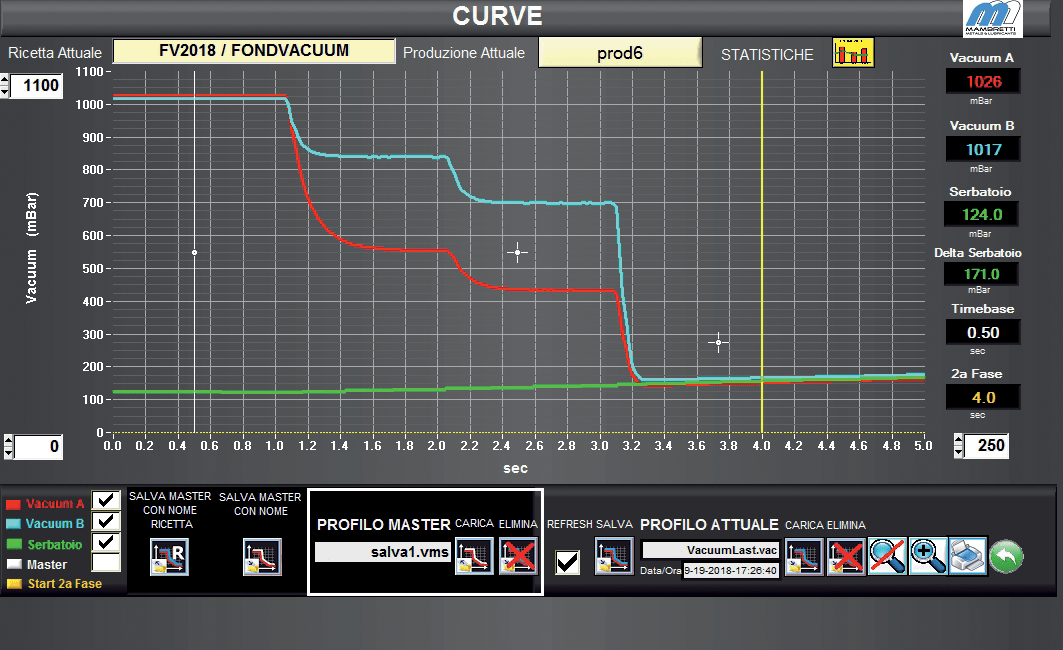

- Representation of the vacuum curve by channel

- Representation of the injection curves of the press that can be superimposed on those of the vacuum

- Process statistics with vacuum levels detection in die casting for each casting

- Set time interval between empty start and fast start phase (1ms tolerance)

- Interface with press safety controls (e.g. empty stop if the press is not operational)

- Control of all types of Fondvacuum valves® and other brands

- Separate vacuum control for the two channels with two adjustable vacuum levels

- Possibility of redirecting all transducer signals remotely onto presses

- Predisposition for Profinet interface with press